Predictive maintenance.

Energy Optimization.

Predictive maintenance.

Energy Optimization.

We are Insens & we eliminate unplanned production downtime and reduce the electrical overconsumption of rotating equipment in industry.

Our RED solution

Increase your productivity with RED, our predictive maintenance solution that allows you to optimize every aspects of your company production lines. Operating 24 hours a day, 7 days a week and connected in real time to our platform, you’ll never miss a failure on your industrial machinery again.

Reduce the energy consumption of your company's equipment by more than 15%!

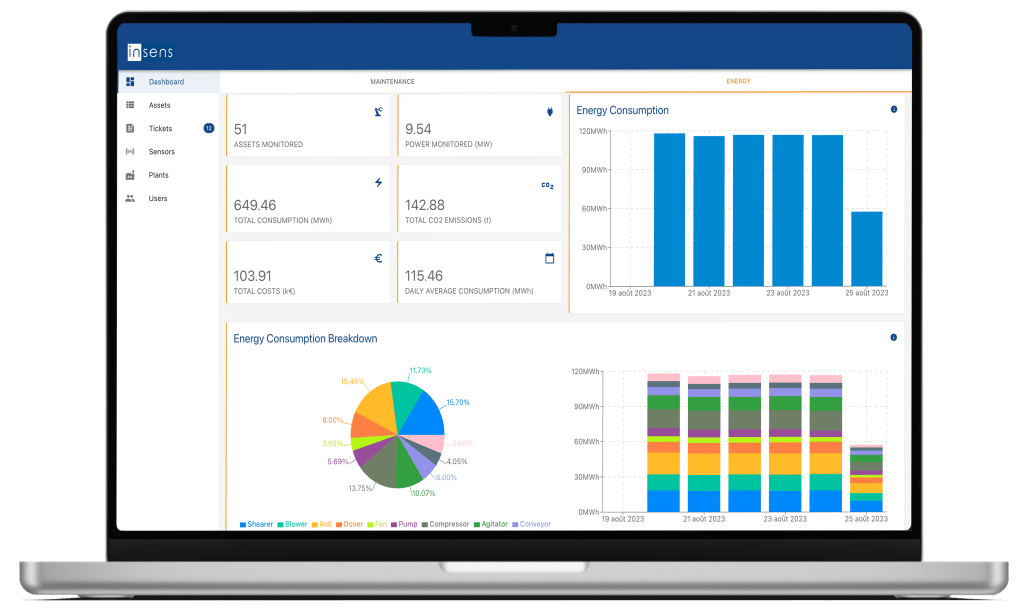

Monitor your data remotely and in real time, and benefit from an energy audit of your machines.

Increase the availability of your production lines by reducing downtime and planning maintenance schedules. RED enables you to make significant savings by reducing unplanned production downtime and optimizing the energy consumption of your production lines.

Reduce your business' CO2 emissions by cutting production downtime, reducing machine breakdowns and optimizing the energy efficiency of your assets.

You'll receive optimization suggestions and be able to quantify the savings you've made and can make!

What is RED ?

1 sensor for the entire drive train

Inside the motor control cabinet

Detect electrical and mechanical faults

Suitable for dangerous or hard-to-reach areas

Detect machine failures before they occur

Our RED system analyzes voltage and current flows, which means it is installed directly in the electrical cabinet supplying your equipment’s production lines. This makes it possible to diagnose future machine failures that are difficult to access!

Continuously connected to your installations, RED collects data from your equipment 24/7, so you don’t miss out on any changes in the behavior of your production lines.

With our online platform, you have access to all data concerning the health of your machines, as well as all our current recommendations and analyses.

Optimize energy consumption

RED can also provide you energy optimization diagnostics, enabling you to make significant savings on the use of your production lines. RED is more than just a predictive maintenance system for reducing equipment downtime.

We’ve also developed our own platform enabling you to consult the health and energy consumption of all your RED-connected machines in real time! So you can always keep an eye on the operating conditions of your production lines.

Want to see our RED system live?

Book a 30 minute demo with our team!

What can you expect from the demo ?

- Live demonstration of our RED solution combining predictive maintenance & energy optimization.

- Discuss your needs and the benefits of working with us.

- Any question you may have!

Testimonials

See for yourself what our customers think of us